PCB BASED CAPACITIVE TOUCH KEYPADS

What is PCB-Based Capacitive Touch Keypads?

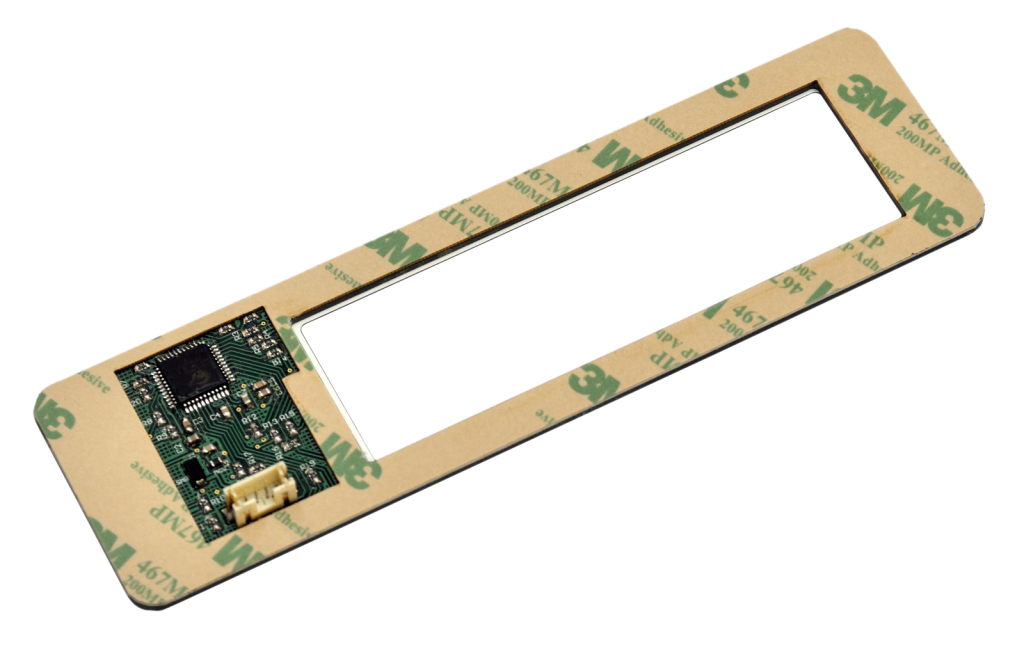

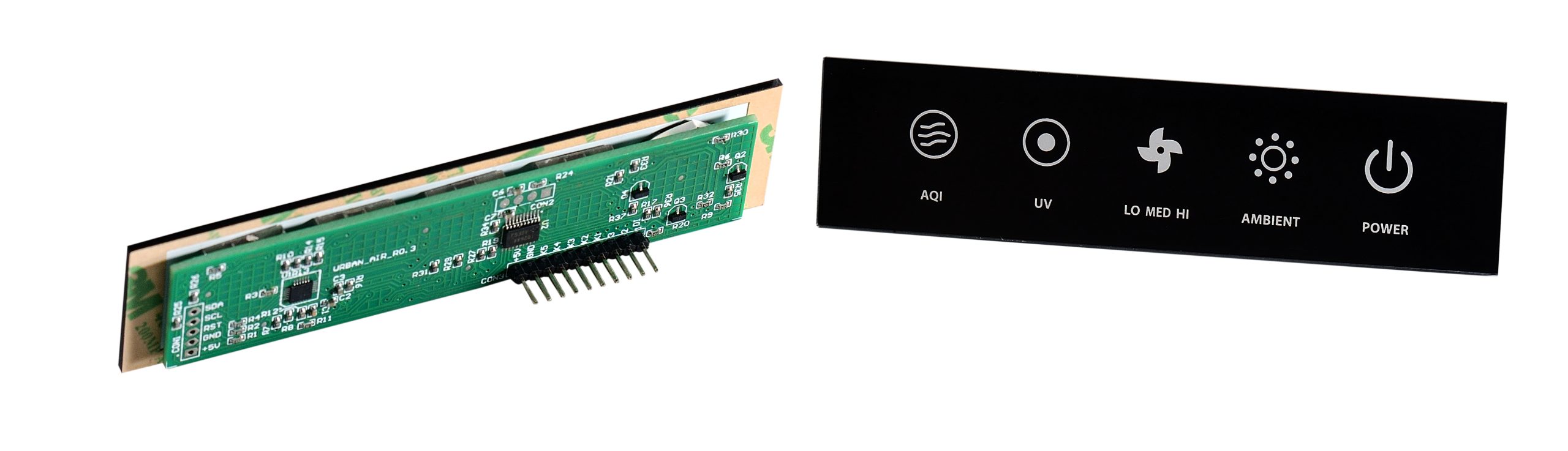

PCB-based capacitive touch keypads are a type of keypad that uses a Printed Circuit Board (PCB) as its foundation. They register touches by detecting changes in capacitance, a measure of an electrical field’s ability to store energy. Unlike traditional keypads with physical buttons, there are no moving parts involved.

Have you ever encountered a control panel with buttons that feel mushy or unresponsive? That’s a thing of the past with PCB-based capacitive touch keypads! These keypads utilize advanced technology to provide a modern and user-friendly experience.

How it Works

A thin layer of insulation separates the PCB circuit board from the user’s touch surface. When a finger nears a designated sensor area, the capacitance changes due to the electrical properties of the human body. This change is detected by the underlying circuitry on the PCB, registering a touch command.

Raw Materials

Several key raw materials go into making PCB-based capacitive touch keypads:

Printed Circuit Board (PCB)

This forms the base of the keypad and is typically made from a laminate material. The most common type uses fiberglass prepreg (FR4), which consists of woven fiberglass cloth impregnated with epoxy resin.

Printed Circuit Board (PCB)

This forms the base of the keypad and is typically made from a laminate material. The most common type uses fiberglass prepreg (FR4), which consists of woven fiberglass cloth impregnated with epoxy resin.

Copper

A thin layer of copper foil is bonded to either side of the FR4 laminate. This copper layer forms the electrical pathways for the circuit.

Copper

A thin layer of copper foil is bonded to either side of the FR4 laminate. This copper layer forms the electrical pathways for the circuit.

Insulation Layer

A thin layer of dielectric material, such as polyimide film, separates the copper layer from the touch surface.

Insulation Layer

A thin layer of dielectric material, such as polyimide film, separates the copper layer from the touch surface.

Top Layer

This can be made from various materials depending on the desired properties. Common options include:

- Glass: Provides a high level of scratch resistance and a clear, high-quality look. Often used for applications demanding durability and a premium feel.

- Acrylic: A more cost-effective option compared to glass. It offers good clarity and can be formed into curved shapes. However, it may be more susceptible to scratches.

- Polycarbonate (PC): Provides a clear and rigid surface for the touch area.

- Polyethylene Terephthalate (PET): A more flexible and cost-effective option.

Top Layer

This can be made from various materials depending on the desired properties. Common options include:

- Glass: Provides a high level of scratch resistance and a clear, high-quality look. Often used for applications demanding durability and a premium feel.

- Acrylic: A more cost-effective option compared to glass. It offers good clarity and can be formed into curved shapes. However, it may be more susceptible to scratches.

- Polycarbonate (PC): Provides a clear and rigid surface for the touch area.

- Polyethylene Terephthalate (PET): A more flexible and cost-effective option.

Benefits of Capacitive Touch Keypads

Sleek Design

PCB keypads are incredibly thin and can even be designed to conform to curved surfaces, creating a modern aesthetic for any application.

Durability

The lack of moving parts makes them highly resistant to wear and tear, extending their lifespan.

Easy Cleaning

The smooth, sealed surface is ideal for environments where hygiene is crucial, as they can be easily cleaned with disinfectants.

Customization

PCB keypads offer a high degree of customization. You can incorporate unique designs, logos, and even backlighting options to match your specific needs.

Touch Sensitivity

These keypads require minimal pressure to activate, providing a comfortable and responsive user experience.

Backlighting Methods

LED Backlighting: LEDs are the most common and versatile backlighting method used in membrane switches. They offer several advantages:

- High Brightness: LEDs provide bright and clear illumination, ensuring that the switch interface is easily visible.

- Customizable Colors: LEDs are available in a wide range of colors, allowing for extensive customization of the switch interface.

- Energy Efficiency: LEDs consume very little power, making them ideal for energy-efficient applications.

- Long Lifespan: LEDs have a long operational life, reducing the need for frequent replacements and maintenance.

Electroluminescent (EL) Panels: EL panels are thin, flexible sheets that emit light when an electric current is applied. They offer several unique advantages:.

- Even Illumination: EL panels provide a uniform glow, ensuring that the entire switch interface is evenly illuminated.

- Thin and Flexible: EL panels are extremely thin and flexible, making them ideal for applications where a low profile is required.

- Low Power Consumption: EL panels consume very little power, making them suitable for energy-efficient applications..

Applications

Capacitive touch keypads offer versatility and are ideal for various applications, including:

Consumer Electronics

Keypads for smartphones, tablets, and other portable devices.

Industrial Controls

User interfaces for machinery and equipment that demand durability and reliability.

Medical Devices

Keypads for medical equipment where hygiene and ease of cleaning are paramount.

Home Appliances

Modernize your appliances with sleek and responsive keypads for microwaves, washing machines, and more.

Choosing the Right Capacitive Touch Keypad

Several factors come into play when selecting a capacitive touch keypad:

- Size and Layout: Consider the available space and the number of keys required for your application.

- Customization Needs: Do you require specific designs, logos, or backlighting options?

- Environmental Factors: Think about potential exposure to moisture or extreme temperatures.

- Compatibility: Ensure the chosen keypad is compatible with your existing system.

The Future of Keypad Technology

PCB-based capacitive touch keypads offer a glimpse into the future of human-machine interaction. Their sleek design, durability, and customization possibilities make them a compelling choice for various applications. Whether you’re a designer, engineer, or simply looking for a more advanced user experience, capacitive touch keypads are worth considering for your next project.